Material extrusion: Difference between revisions

No edit summary |

No edit summary |

||

| (27 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

[[File:PXL 20230914 175310736.jpg|right|frameless|430x430px]] | [[File:PXL 20230914 175310736.jpg|right|frameless|430x430px]] | ||

[[File:PXL 20230914 182737949.jpg|right|frameless|429x429px]] | |||

[[File:PXL 20230914 185334611.jpg|right|frameless|429x429px]] | |||

== Process Description == | == Process Description == | ||

Material extrusion is the most common form of additive manufacturing technology | Material extrusion is the most common form of additive manufacturing technology. This method works by melting or softening the material, and combining it to old layers to produce a part. Other names for it are fused filament fabrication and fused deposition modeling (FDM). | ||

Filament is fed from a large spool through a moving, heated printer extruder head, and is deposited on the growing work. The print head is moved under computer control to define the printed shape. Usually the head moves in two dimensions to deposit one horizontal plane, or layer, at a time; the work or the print head is then moved vertically by a small amount to begin a new layer. The speed of the extruder head may also be controlled to stop and start deposition and form an interrupted plane without stringing or dribbling between sections. | In fused deposition modeling, the part is produced by extruding small beads or streams of material that harden immediately to form layers. Filament is fed from a large spool through a moving, heated printer extruder head, and is deposited on the growing work. The print head is moved under computer control to define the printed shape. Usually, the head moves in two dimensions to deposit one horizontal plane, or layer, at a time; the work or the print head is then moved vertically by a small amount to begin a new layer. The speed of the extruder head may also be controlled to stop and start deposition and form an interrupted plane without stringing or dribbling between sections. | ||

== Strengths & Weaknesses == | == Strengths & Weaknesses == | ||

* | === Strengths === | ||

* | * '''Budget-friendly:''' Material extrusion technology has been around long enough that there many printers are available for a few hundred dollars or less. These allow for a low access point for those who are interested in getting into printing, but unsure of the process. | ||

* '''Ease of use:''' Many material extrusion printers require very little training to use. Also, if there is a problem there is a significant amount of free online information to help. | |||

=== Weaknesses === | |||

* '''Surface finish:''' Due to the way that parts are created, layer lines will almost always be visible. Typically, higher quality printers will have a betters surface finish. | |||

* '''Need for support:''' Material extrusion printers have difficulty in printing parts with overhangs, so they need to add extra material to give a stable platform for printing. These can often be removed, but sometimes this is difficult, it creates material waste, and it negatively affects the surface finish. | |||

* '''Warping:''' Temperature differences can cause uneven contractions in a part while it's printing, leaving a warped part. Printers with a heated bed and proper enclosure can mitigate this issue. | |||

== Machine Ranges == | |||

Overall, this printing technology can produce parts of moderate size and resolution for low prices. To see a general comparison of how this technology stacks up with other technologies, see the [[Main Page|main page]]. | |||

{| class="wikitable" | {| class="wikitable" | ||

|+ | |+ | ||

! | ! | ||

! | !Worst | ||

! | !Best | ||

|- | |- | ||

| | |Volume X/Y/Z (mm) | ||

|120/68/150 | |120/68/150 | ||

|1005/1005/1005 | |1005/1005/1005 | ||

|- | |- | ||

| | |Resolution (mm) | ||

|1 | |||

|.25 | |.25 | ||

|- | |- | ||

| | |Layer Height (um) | ||

|300 | |||

|20 | |20 | ||

|- | |- | ||

| | |Price ($) | ||

|27,475 | |||

|200 | |200 | ||

| | |- | ||

|Weight(kg) | |||

|2869 | |||

|4 | |||

|- | |||

|Build Rate(cm^3/hr) | |||

|16 | |||

|130 | |||

|} | |||

[[File:Bl P1P.webp|none|thumb|[https://us.store.bambulab.com/products/p1p Bambu Lab P1P]]] | |||

{| class="wikitable" | |||

!Build Volume | |||

!Layer Height | |||

!Resolution | |||

!Size xyz | |||

! Power | |||

!Price | |||

!Weight | |||

|- | |||

|256/256/256mm | |||

|50um | |||

|.2mm | |||

|386/389/458mm | |||

|350W | |||

|699$ | |||

|14.3kg | |||

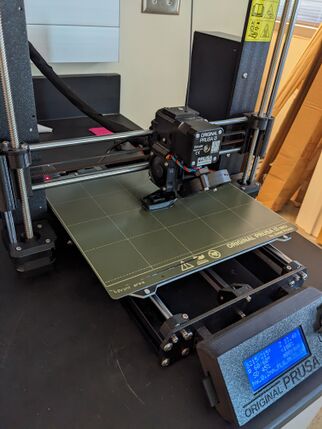

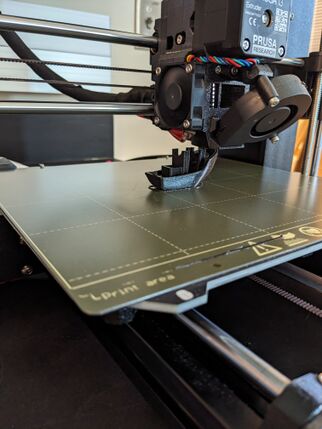

|}[[File:Prussa mk4.jpg|none|thumb|[https://www.prusa3d.com/category/original-prusa-mk4/ Prusa mk4]]] | |||

{| class="wikitable" | |||

!Build Volume | |||

!Layer Height | |||

!Resolution | |||

!Size xyz | |||

! Power | |||

!Price | |||

!Weight | |||

|- | |||

|250/210/220mm | |||

|50um | |||

|.4mm | |||

|500/500/400mm | |||

|120W | |||

|1099$ | |||

|7kg | |||

|} | |} | ||

== Technologies == | == Technologies == | ||

There are a | There are a couple of technologies that can significantly art the types of parts produced by Material Extrusion when compared to most baseline printers. | ||

* '''Metal replacement''' (Bound metal deposition/Atomic diffusion): With this technology, metal particles are infused into a thermal plastic. The printed part is put through a secondary process to remove the thermal plastic leaving a smaller metal part in its place. | |||

* '''Continuous fiber reinforcement:''' A second print head lays down continuous fiber such as carbon fiber, fiberglass, or Kevlar into the internal structure of a print. This gives the part stronger material properties. | |||

==Navigation== | |||

*[https://omic-am.mme.pdx.edu/index.php/Main_Page?veaction=edit Home page] | |||

*[[Material extrusion|Material Extrusion]] | |||

*[[Powder Bed Fusion]] | |||

*[[Vat Polymerization]] | |||

*[[Direct Energy Deposition]] | |||

*[[Binder Jetting]] | |||

*[[Material Jetting]] | |||

*[[Sheet Lamination]] | |||

== References == | |||

Rosen, Stucker, and Khorasani, Additive Manufacturing Technologies, chap. 6. | |||

“Material Extrusion - FDM | Make.” Accessed October 6, 2023. <nowiki>https://make.3dexperience.3ds.com/processes/material-extrusion</nowiki>. | |||

Latest revision as of 14:37, 13 October 2023

Process Description

Material extrusion is the most common form of additive manufacturing technology. This method works by melting or softening the material, and combining it to old layers to produce a part. Other names for it are fused filament fabrication and fused deposition modeling (FDM).

In fused deposition modeling, the part is produced by extruding small beads or streams of material that harden immediately to form layers. Filament is fed from a large spool through a moving, heated printer extruder head, and is deposited on the growing work. The print head is moved under computer control to define the printed shape. Usually, the head moves in two dimensions to deposit one horizontal plane, or layer, at a time; the work or the print head is then moved vertically by a small amount to begin a new layer. The speed of the extruder head may also be controlled to stop and start deposition and form an interrupted plane without stringing or dribbling between sections.

Strengths & Weaknesses

Strengths

- Budget-friendly: Material extrusion technology has been around long enough that there many printers are available for a few hundred dollars or less. These allow for a low access point for those who are interested in getting into printing, but unsure of the process.

- Ease of use: Many material extrusion printers require very little training to use. Also, if there is a problem there is a significant amount of free online information to help.

Weaknesses

- Surface finish: Due to the way that parts are created, layer lines will almost always be visible. Typically, higher quality printers will have a betters surface finish.

- Need for support: Material extrusion printers have difficulty in printing parts with overhangs, so they need to add extra material to give a stable platform for printing. These can often be removed, but sometimes this is difficult, it creates material waste, and it negatively affects the surface finish.

- Warping: Temperature differences can cause uneven contractions in a part while it's printing, leaving a warped part. Printers with a heated bed and proper enclosure can mitigate this issue.

Machine Ranges

Overall, this printing technology can produce parts of moderate size and resolution for low prices. To see a general comparison of how this technology stacks up with other technologies, see the main page.

| Worst | Best | |

|---|---|---|

| Volume X/Y/Z (mm) | 120/68/150 | 1005/1005/1005 |

| Resolution (mm) | 1 | .25 |

| Layer Height (um) | 300 | 20 |

| Price ($) | 27,475 | 200 |

| Weight(kg) | 2869 | 4 |

| Build Rate(cm^3/hr) | 16 | 130 |

| Build Volume | Layer Height | Resolution | Size xyz | Power | Price | Weight |

|---|---|---|---|---|---|---|

| 256/256/256mm | 50um | .2mm | 386/389/458mm | 350W | 699$ | 14.3kg |

| Build Volume | Layer Height | Resolution | Size xyz | Power | Price | Weight |

|---|---|---|---|---|---|---|

| 250/210/220mm | 50um | .4mm | 500/500/400mm | 120W | 1099$ | 7kg |

Technologies

There are a couple of technologies that can significantly art the types of parts produced by Material Extrusion when compared to most baseline printers.

- Metal replacement (Bound metal deposition/Atomic diffusion): With this technology, metal particles are infused into a thermal plastic. The printed part is put through a secondary process to remove the thermal plastic leaving a smaller metal part in its place.

- Continuous fiber reinforcement: A second print head lays down continuous fiber such as carbon fiber, fiberglass, or Kevlar into the internal structure of a print. This gives the part stronger material properties.

- Home page

- Material Extrusion

- Powder Bed Fusion

- Vat Polymerization

- Direct Energy Deposition

- Binder Jetting

- Material Jetting

- Sheet Lamination

References

Rosen, Stucker, and Khorasani, Additive Manufacturing Technologies, chap. 6.

“Material Extrusion - FDM | Make.” Accessed October 6, 2023. https://make.3dexperience.3ds.com/processes/material-extrusion.