Vat Polymerization: Difference between revisions

No edit summary |

No edit summary |

||

| (13 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

== Process description== | == Process description== | ||

Vat polymerization was | [[File:Resin print.png|right|frameless]] | ||

Vat polymerization was first developed by Charles Hull in 1986. This process starts with a print plate being placed on the very top of a vat filled with a photo-reactive resin. A light source is then used to cure the first layer and bond it to the bottom of the plate. The plate is then raised so that the next layer is cured directly onto the last. This is repeated until the part is complete. The part then washed and further hardened with a strong light. | |||

== | == Strengths & Weaknesses == | ||

* | === Strengths === | ||

* | * '''High resolution and surface finish:''' This process has the highest resolution of all additive manufacturing technologies since detail is only limited by screen resolution | ||

*'''Clear parts:''' The material used in Vat Polymerization allows for the creation of clear parts. | |||

== | === Weaknesses === | ||

* '''Toxic materials:''' Most materials used in Vat Polymerization are generally extremely toxic, and should be handled with care. Protective equipment should be worn, and printing should always be done with proper ventilation to protect against toxic fumes. | |||

* '''Weaker material properties:''' Resins that are used in this process tend to be brittle and not very tough. | |||

* '''Post processing:''' VP parts need to be cleaned of wet resin, and cured a second time to ensure hardness and layer bonding. | |||

*'''Resin degradation:''' Resins tend to degrade in color and strength over time, especially if exposed to environmental elements. | |||

== Machine Ranges == | |||

Vat Polymerization produces relatively small parts with the highest resolution of any technologies. Printers can be affordable, or on the more expensive side, depending on the size and quality of prints desired. | |||

{| class="wikitable" | {| class="wikitable" | ||

! | ! | ||

! | !Worst | ||

! | !Best | ||

|- | |- | ||

|volume X/Y/Z (mm) | |volume X/Y/Z (mm) | ||

| Line 27: | Line 31: | ||

|- | |- | ||

|layer height (um) | |layer height (um) | ||

|25 | |||

|15 | |15 | ||

|- | |- | ||

|price ($) | |price ($) | ||

|500,000 | |||

|450 | |450 | ||

| | |- | ||

|Weight kg | |||

|1724 | |||

|5 | |||

|- | |||

|build rate | |||

|2 | |||

|12 | |||

|} | |||

[[File:ProX 950.jpg|none|thumb|[https://www.3dsystems.com/3d-printers/prox-950 ProX 950]<nowiki/>]] | |||

{| class="wikitable" | |||

!Build Volume | |||

!Layer Height | |||

! Resolution | |||

!Size xyz | |||

!power | |||

!Price | |||

!Weight | |||

|- | |||

|1500/750/550mm | |||

|50um | |||

|.13mm | |||

|2200/1600/2260mm | |||

|1450mW | |||

|Requires Quote | |||

|907 | |||

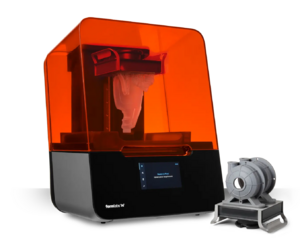

|}[[File:Form 3+.webp|none|thumb|[https://shorturl.at/ptwAX form 3+]]] | |||

{| class="wikitable" | |||

!Build volume | |||

!Layer Height | |||

! Resolution | |||

!Size xyz | |||

!Power | |||

!Price | |||

!Weight | |||

|- | |||

|145/145/145mm | |||

|25um | |||

|.025mm | |||

|386/389/458mm | |||

|250mw | |||

|2,499$ | |||

|17.5 | |||

|} | |} | ||

==Technologies== | ==Technologies== | ||

There are a | There are two main technologies used for curing resins in Vat Polymerization printing: | ||

* '''Digital Light Processing''' (DLP): This uses a projector to cast the entire image of each layer for curing at the same time. This process is fast but with the trade off of decreasing accuracy. | |||

* '''Stereolithography''': This processes uses a laser to cure a single section of the layer at a time, similar to Powder Bed Fusion. This enables higher resolution parts, but is slower. | |||

==Navigation== | |||

*[https://omic-am.mme.pdx.edu/index.php/Main_Page?veaction=edit Home page] | |||

*[[Material extrusion|Material Extrusion]] | |||

*[[Powder Bed Fusion]] | |||

*[[Vat Polymerization]] | |||

*[[Direct Energy Deposition]] | |||

*[[Binder Jetting]] | |||

*[[Material Jetting]] | |||

*[[Sheet Lamination]] | |||

==References== | |||

Rosen, Stucker, and Khorasani, Additive Manufacturing Technologies, chap. 4. | |||

“Photopolymerization - VAT, SLA, DLP, CDLP | Make.” Accessed October 6, 2023. <nowiki>https://make.3dexperience.3ds.com/processes/photopolymerization</nowiki>. | |||

Latest revision as of 14:44, 13 October 2023

Process description

Vat polymerization was first developed by Charles Hull in 1986. This process starts with a print plate being placed on the very top of a vat filled with a photo-reactive resin. A light source is then used to cure the first layer and bond it to the bottom of the plate. The plate is then raised so that the next layer is cured directly onto the last. This is repeated until the part is complete. The part then washed and further hardened with a strong light.

Strengths & Weaknesses

Strengths

- High resolution and surface finish: This process has the highest resolution of all additive manufacturing technologies since detail is only limited by screen resolution

- Clear parts: The material used in Vat Polymerization allows for the creation of clear parts.

Weaknesses

- Toxic materials: Most materials used in Vat Polymerization are generally extremely toxic, and should be handled with care. Protective equipment should be worn, and printing should always be done with proper ventilation to protect against toxic fumes.

- Weaker material properties: Resins that are used in this process tend to be brittle and not very tough.

- Post processing: VP parts need to be cleaned of wet resin, and cured a second time to ensure hardness and layer bonding.

- Resin degradation: Resins tend to degrade in color and strength over time, especially if exposed to environmental elements.

Machine Ranges

Vat Polymerization produces relatively small parts with the highest resolution of any technologies. Printers can be affordable, or on the more expensive side, depending on the size and quality of prints desired.

| Worst | Best | |

|---|---|---|

| volume X/Y/Z (mm) | 96/54/127 | 380/380/250 |

| resolution (mm) | .05 | .003 |

| layer height (um) | 25 | 15 |

| price ($) | 500,000 | 450 |

| Weight kg | 1724 | 5 |

| build rate | 2 | 12 |

| Build Volume | Layer Height | Resolution | Size xyz | power | Price | Weight |

|---|---|---|---|---|---|---|

| 1500/750/550mm | 50um | .13mm | 2200/1600/2260mm | 1450mW | Requires Quote | 907 |

| Build volume | Layer Height | Resolution | Size xyz | Power | Price | Weight |

|---|---|---|---|---|---|---|

| 145/145/145mm | 25um | .025mm | 386/389/458mm | 250mw | 2,499$ | 17.5 |

Technologies

There are two main technologies used for curing resins in Vat Polymerization printing:

- Digital Light Processing (DLP): This uses a projector to cast the entire image of each layer for curing at the same time. This process is fast but with the trade off of decreasing accuracy.

- Stereolithography: This processes uses a laser to cure a single section of the layer at a time, similar to Powder Bed Fusion. This enables higher resolution parts, but is slower.

- Home page

- Material Extrusion

- Powder Bed Fusion

- Vat Polymerization

- Direct Energy Deposition

- Binder Jetting

- Material Jetting

- Sheet Lamination

References

Rosen, Stucker, and Khorasani, Additive Manufacturing Technologies, chap. 4.

“Photopolymerization - VAT, SLA, DLP, CDLP | Make.” Accessed October 6, 2023. https://make.3dexperience.3ds.com/processes/photopolymerization.