Direct Energy Deposition: Difference between revisions

No edit summary |

|||

| (5 intermediate revisions by the same user not shown) | |||

| Line 24: | Line 24: | ||

!Best | !Best | ||

|- | |- | ||

| | |Volume X/Y/Z (mm) | ||

|200/200/200 | |200/200/200 | ||

|5080/2794/2794 | |5080/2794/2794 | ||

|- | |- | ||

| | |Resolution (mm) | ||

|1 | |1 | ||

| .67 | | .67 | ||

|- | |- | ||

| | |Layer Height (um) | ||

|1000 | |1000 | ||

|800 | |800 | ||

|- | |||

|Price ($) | |||

|Requires | |||

|Quotes | |||

|} | |} | ||

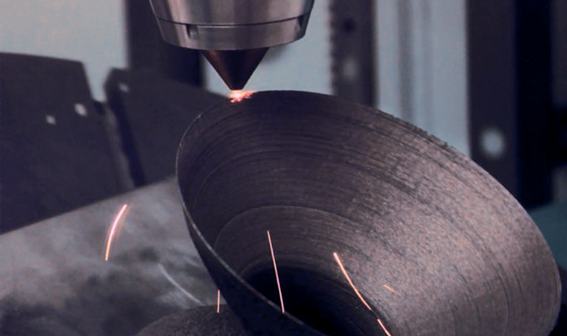

[[File:Optomec-cs250.webp|none|thumb|Lens cs 600<nowiki/> ]] | [[File:Optomec-cs250.webp|none|thumb|[https://optomec.com/lens-cs-600-system/ Lens cs 600]<nowiki/> ]] | ||

{| class="wikitable" | {| class="wikitable" | ||

!Build volume | !Build volume | ||

! | !Resolution | ||

! | !Size xyz | ||

! | !Power | ||

!Price | |||

|- | |- | ||

|600/400/400mm | |600/400/400mm | ||

| Line 47: | Line 52: | ||

|2800/2700/2450mm | |2800/2700/2450mm | ||

|2kw | |2kw | ||

|Requires Quote | |||

|} | |} | ||

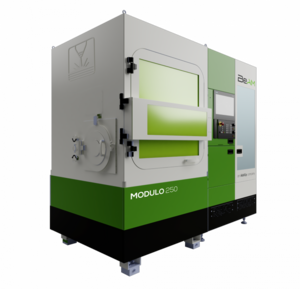

[[File:Modulo 250.png|none|thumb|modulo 250]] | [[File:Modulo 250.png|none|thumb|[https://addupsolutions.com/machines/ded/ modulo 250]]] | ||

{| class="wikitable" | {| class="wikitable" | ||

!Build volume | !Build volume | ||

! | !Layer Height | ||

! | !Resolution | ||

! | !Size xyz | ||

! | !Power | ||

!Price | |||

|- | |- | ||

|400/250/300mm | |400/250/300mm | ||

| Line 61: | Line 68: | ||

|386/389/458mm | |386/389/458mm | ||

|1kw | |1kw | ||

|Requires Quote | |||

|} | |} | ||

==Categories of DED== | ==Categories of DED== | ||

Latest revision as of 12:41, 24 October 2023

Process description

Direct Energy Deposition (DED) combines welding with other technologies to produce parts through additive manufacturing. In this process, a high power heat source is used to melt and deposit a feed stock directly onto a plate (typically welding it onto a sacrificial print bed). Each layer is welded onto the last until the part is fully formed. The part must then be cut from the build plate, and post processed, usually through subtractive manufacturing such as milling, to produce a finished product.

DED also has the unique ability to modify existing metal parts. By treating the old part as the print surface, it can build out new layers, similar to printing on a traditional build plate.

Strengths & Weaknesses

Strengths

- Industrial scaling: DED machines are often much larger then other print types, enabling the production of fairly large parts.

- Part modification: DED has the ability to add additional features onto weldable metal parts, allowing for the combination of different manufacturing technologies or repair of broken parts.

Weaknesses

- Surface finish: Although the exact surface finish is dependent on the feed stocked, DED has very poor surface finish in general.

- High energy: The constant melting of metal in the process uses very high amounts of energy.

- Post processing: DED prints often need to be machined to fix geometries and surface finishes.

- HIgh Cost:

Machine Ranges

DED has the ability to make large parts out of metal, however the resolution is relatively low compared to other methods.

| Worst | Best | |

|---|---|---|

| Volume X/Y/Z (mm) | 200/200/200 | 5080/2794/2794 |

| Resolution (mm) | 1 | .67 |

| Layer Height (um) | 1000 | 800 |

| Price ($) | Requires | Quotes |

| Build volume | Resolution | Size xyz | Power | Price |

|---|---|---|---|---|

| 600/400/400mm | .67mm | 2800/2700/2450mm | 2kw | Requires Quote |

| Build volume | Layer Height | Resolution | Size xyz | Power | Price |

|---|---|---|---|---|---|

| 400/250/300mm | 800um | .1mm | 386/389/458mm | 1kw | Requires Quote |

Categories of DED

The two primary factors used to characterize DED printers is based on the type of feed stock and the type of energy source used to melt the parts

Feed type

- Wire fed: Wire feeding gives a consistent flow of material to the deposition pool. This Leads to similar problems that material extrusions printers experience such as the geometry being limted to the fixed diameter of the material deposition, and a slight bulging causing bumpy surface finish

- Powder fed: Powder methods enable more complex geometries to be produced by changing the amount of powder deposited in a particular area. However, not all material being deposited ends up being used, and a recycling system must be used to prevent powder waste.

Energy sources

- Laser: Laser based DED systems allow for precise control over the heat source. Lasers paired with powder are capable of producing the most complex geometries in this category of AM.

- Plasma: This tends to be the most energy efficient form of DED. Normally paired with wire feedstock, it is best suited for large scale manufacturing.

- Electron beam: This is one of the less common energy sources for DED systems. It is very fast, however, it must be done in a vacuum, increasing costs, but reducing potential contamination of the parts.

Technologies

- Wire Arc Additive Manufacturing (WAAM): The generic term for the combination of a plasma energy source and a wire feedstock.

- Powder Laser (PL): The generic term for a combination of a powder feed source with a laser energy source.

- Laser Engineered Net Shaping (LENS): A proprietary technology created by Optomec that combines a laser power source and a powder feeding system.

- Electron Beam Additive Manufacturing (EBAM): A proprietary technology created by Sciaky that combines an electron beam energy source, and a wire feedstock.

- Rapid Plasma Deposition (RPD): A proprietary technology created by Norsk titanium that is an advanced version of WAAM.

- Home page

- Material Extrusion

- Powder Bed Fusion

- Vat Polymerization

- Direct Energy Deposition

- Binder Jetting

- Material Jetting

- Sheet Lamination

References

Rosen, Stucker, and Khorasani, Additive Manufacturing Technologies, chap. 10.

“Directed Energy Deposition - DED, LENS, EBAM | Make.” Accessed August 10, 2023. https://make.3dexperience.3ds.com/processes/directed-energy-deposition.