Powder Bed Fusion: Difference between revisions

No edit summary |

|||

| (21 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

== Process description == | == Process description == | ||

[[File:PXL 20230828 231728663.jpg|right|frameless|422x422px]] | |||

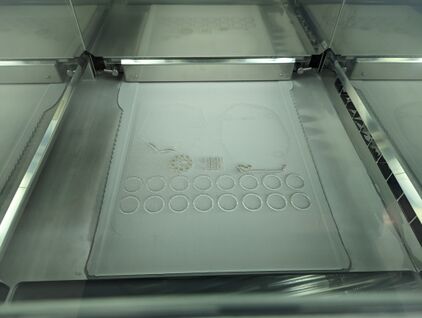

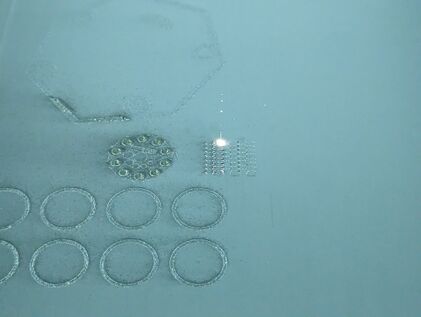

Powder bed fusion is primarily used to build metal parts, although other materials may be used. Powder bed fusion works by spreading a layer of powdered material over the entire print surface and then using a laser to selectively melt sections together. Another layer is then added on top of the last and the process is repeated until the part is complete. After the part is built, it must be thoroughly cleaned and scrubbed to remove excess powder. | |||

==Strengths & Weaknesses== | |||

== | === Strengths === | ||

*'''Built in support system:''' The excess powder supports the print so there's no need to add printed supports, enabling the building of more complex geometries while maintaining consistent surface finish throughout the part. | |||

* '''Small footprint''': Powder bed fusion machines frequently have a small footprint, and can be added into most workplaces. This allows for organizations to create metal prototypes in house. | |||

* ''' | === Weaknesses === | ||

* ''' | *'''High energy use:''' Melting metal with a laser takes significant energy. | ||

* '''Surface finish:''' Powder bed fusion generally has a rough surface finish. | |||

* '''Material properties:''' This process produces a weaker grain structure compared to parts cast from the same material. | |||

[[File:PXL 20230828 232002915.jpg|right|frameless|421x421px]] | |||

[[File:PXL 20230817 210159504.jpg|right|frameless|421x421px]] | |||

== Machine Ranges == | |||

Overall, this technology can produce smaller parts with high dimensional accuracy. Powder bed fusion printers are on the more expensive side and require quotes from individual companies. Our research indicates these machines are on the order of $1,600,000. | |||

{| class="wikitable" | {| class="wikitable" | ||

! | ! | ||

! | !Worst | ||

! | !Best | ||

|- | |- | ||

|volume X/Y/Z (mm) | |volume X/Y/Z (mm) | ||

| Line 23: | Line 31: | ||

|resolution (mm) | |resolution (mm) | ||

|.1 | |.1 | ||

| | |.06 | ||

|- | |- | ||

|layer height (um) | |layer height (um) | ||

|120 | |120 | ||

|20 | |||

|- | |- | ||

|price ($) | |price ($) | ||

| | |Requires | ||

| | |Quotes | ||

|- | |||

|Weight(kg) | |||

|4635 | |||

|1060 | |||

|- | |||

|Build rate (cm^3/hr) | |||

|20 | |||

|120 | |||

|} | |||

[[File:Dmp-flex-350.webp|none|thumb|[https://www.3dsystems.com/3d-printers/dmp-flex-350 Dmp-flex-350]]] | |||

{| class="wikitable" | |||

!Build volume | |||

!layer Height | |||

!resolution | |||

!size xyz | |||

!Price | |||

!Weight | |||

|- | |||

|275/275/420mm | |||

|60um | |||

|.005mm | |||

| 2370/2400/3470mm | |||

|Requires Quote | |||

|4200 | |||

|}[[File:SPro 230.webp|none|thumb|[https://support.3dsystems.com/s/3d-printers/spro-140-and-230?language=en_US SPro 230]<nowiki/>]] | |||

{| class="wikitable" | |||

!Build Volume | |||

!Layer Height | |||

!Resolution | |||

!Size xyz | |||

!Power | |||

!Price | |||

!Weight | |||

|- | |||

|256/256/256mm | |||

|50um | |||

|.2mm | |||

| 386/389/458mm | |||

|350W | |||

|Requires Quote | |||

|2541 | |||

|} | |} | ||

== Technologies == | == Technologies == | ||

There are | There are two main classes of Powder Bed Fusion printers that describe the laser process and typically indicate the type of materials it uses. | ||

'''Selective Laser Sintering (SLS)''': This is the general term for non-metal powder bed fusion technologies. The term indicates that the heat source only adds enough energy to fuse the powder instead of fully melting it. SLS printing can provide improved capabilities when compared to material extrusion for softer materials such as as nylon or softer thermoplastics. | |||

'''Selective Laser Melting (SLM)''': In contrast to SLS, SLM refers to processes of metal powder bed fusion. The energy added completely melts the material, making the internal structure more homogenous. This technique produces fully metal prototypes relatively easily. | |||

==Navigation== | |||

*[https://omic-am.mme.pdx.edu/index.php/Main_Page?veaction=edit Home page] | |||

*[[Material extrusion|Material Extrusion]] | |||

*[[Powder Bed Fusion]] | |||

*[[Vat Polymerization]] | |||

*[[Direct Energy Deposition]] | |||

*[[Binder Jetting]] | |||

*[[Material Jetting]] | |||

*[[Sheet Lamination]] | |||

==References== | |||

Rosen, Stucker, and Khorasani, Additive Manufacturing Technologies, chap. 5. | |||

“Powder Bed Fusion - DMLS, SLS, SLM, MJF, EBM | Make.” Accessed October 6, 2023. <nowiki>https://make.3dexperience.3ds.com/processes/powder-bed-fusion</nowiki>. | |||

Latest revision as of 08:06, 16 October 2023

Process description

Powder bed fusion is primarily used to build metal parts, although other materials may be used. Powder bed fusion works by spreading a layer of powdered material over the entire print surface and then using a laser to selectively melt sections together. Another layer is then added on top of the last and the process is repeated until the part is complete. After the part is built, it must be thoroughly cleaned and scrubbed to remove excess powder.

Strengths & Weaknesses

Strengths

- Built in support system: The excess powder supports the print so there's no need to add printed supports, enabling the building of more complex geometries while maintaining consistent surface finish throughout the part.

- Small footprint: Powder bed fusion machines frequently have a small footprint, and can be added into most workplaces. This allows for organizations to create metal prototypes in house.

Weaknesses

- High energy use: Melting metal with a laser takes significant energy.

- Surface finish: Powder bed fusion generally has a rough surface finish.

- Material properties: This process produces a weaker grain structure compared to parts cast from the same material.

Machine Ranges

Overall, this technology can produce smaller parts with high dimensional accuracy. Powder bed fusion printers are on the more expensive side and require quotes from individual companies. Our research indicates these machines are on the order of $1,600,000.

| Worst | Best | |

|---|---|---|

| volume X/Y/Z (mm) | 250/250/325 | 800/400/500 |

| resolution (mm) | .1 | .06 |

| layer height (um) | 120 | 20 |

| price ($) | Requires | Quotes |

| Weight(kg) | 4635 | 1060 |

| Build rate (cm^3/hr) | 20 | 120 |

| Build volume | layer Height | resolution | size xyz | Price | Weight |

|---|---|---|---|---|---|

| 275/275/420mm | 60um | .005mm | 2370/2400/3470mm | Requires Quote | 4200 |

| Build Volume | Layer Height | Resolution | Size xyz | Power | Price | Weight |

|---|---|---|---|---|---|---|

| 256/256/256mm | 50um | .2mm | 386/389/458mm | 350W | Requires Quote | 2541 |

Technologies

There are two main classes of Powder Bed Fusion printers that describe the laser process and typically indicate the type of materials it uses.

Selective Laser Sintering (SLS): This is the general term for non-metal powder bed fusion technologies. The term indicates that the heat source only adds enough energy to fuse the powder instead of fully melting it. SLS printing can provide improved capabilities when compared to material extrusion for softer materials such as as nylon or softer thermoplastics.

Selective Laser Melting (SLM): In contrast to SLS, SLM refers to processes of metal powder bed fusion. The energy added completely melts the material, making the internal structure more homogenous. This technique produces fully metal prototypes relatively easily.

- Home page

- Material Extrusion

- Powder Bed Fusion

- Vat Polymerization

- Direct Energy Deposition

- Binder Jetting

- Material Jetting

- Sheet Lamination

References

Rosen, Stucker, and Khorasani, Additive Manufacturing Technologies, chap. 5.

“Powder Bed Fusion - DMLS, SLS, SLM, MJF, EBM | Make.” Accessed October 6, 2023. https://make.3dexperience.3ds.com/processes/powder-bed-fusion.